Planting

Seedlings are purchased only from certified nurseries with checked background. The varietal selection is determined considering many factors such as: cupping quality, yield, resistance to pests and diseases, and easy adaptation to local climate and soil.

Harvesting

Hand-picking and mechanical harvesting.

Harvesting is made according to the coffee tree own needs. On the younger and therefore more delicate trees, the coffee cherries are hand-picked. For the stronger and more robust trees, it is done the selective mechanized harvesting. Therefore, the machine can be adjusted to harvest with less power, speed and less rods, so only the mature cherries will fall out of the tree. The other cherries will remain on the trees, until they mature. Then the machine can go on the fields one or two more times, until all cherries are harvested on the right maturation pointHand picking is also used for the microlots production.

Wet-Milling

Wet Mill

The wet mill structure cleans and separate coffee cherries through a water flow system.

After cleaning, the cherries are separated according to its maturation through a flotation system: the dryer and over-ripe cherries will float, and the mature (red or yellow) and immature cherries (green) will sink. Therefore, the dry cherries usually will be processed as “Naturals” and will be dried on the patio with its pulp and husk on.

The mature cherries that sank can be dried the same way or it can be pulped and dried as “Pulped” or “Semi-washed” coffees. The decision of which way the cherries will be processed will be directed by the Quality department, that previously, cups a coffee sample, in each process. This allows the team to take the best approach possible aiming the highest quality for the beans.

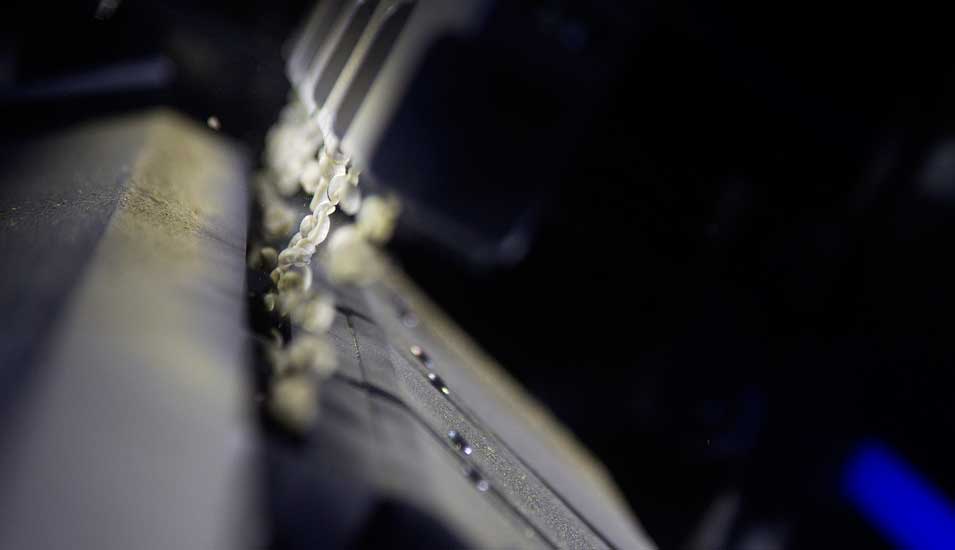

Wet Mill

The pulping process consists on the water flow pressuring the cherries against a sieve. As the immature beans are harder, they don’t get peeled or pulped during this process and are discarded through another channel for a lower quality coffee production.

All this process is made with the last available technology using the least possible water.

The farm also uses the controlled aerobic and anaerobic fermentation process, for the microlots production.

Pulped Coffee

Natural Coffee

Patios

Concrete patio and African bed.

After the wet milling process, the drying process starts.

The first phase of this process is on the patios, making use of an abundant natural resource in Brazil, especially in this microregion: the sun! The farm has 8.000 m2 of concrete patios – that allows the drying of the beans to be made with gentle temperatures, not risking to “burn” the beans. Concrete doesn’t get as hot as other materials like asphalt for example.

For the microlots, the farm counts on the “african beds” for drying, not allowing the beans to touch the ground.

Dryers

Dryers temperature control and Drum Dryers.

After the first phase under the sun, the beans will go through a final and homogenizing drying in the drum dryers. This is very important, because differently from the sun drying, hot air flow and temperature can be stable and controlled.

The 20 drum dryers used at Nossa Senhora de Fátima farm, are electronically controlled. This system replaces the manual control, therefore avoid lots being poorly dryed because of human mistakes. It also provides stable entry and mass temperature throughout the process, avoiding up to 60% waste on the oven’s fuel – wood.

Silos

Fazenda Nossa Senhora de Fátima silos can store up to 40.000 bags.

Therefore, the farm is self-sufficient towards warehousing and there is no need to use a 3rd part warehouse in any phase of production.

Benefit and rebenefit

Zancanaro’s Family farm is the only one in the state of Goiás to have its own complete dry mill structure. It covers all steps to deliver an exceptional and selected product to meet internal and international market demands:

Sticks and stones cleaner

Hulling

Air flow selection

Density selection

Screen size selection

Bichromatic electronic sorting

Scale and bagging

For exports, containers are sealed at the farm, avoiding any handling of the product during logistics to the Port.